Working in Space Isn’t as Simple as Grabbing a Wrench

Imagine you’re floating 400 kilometers above Earth on the International Space Station. A bolt needs tightening, but there’s no gravity, no hardware store, and no second chances — drop a wrench, and it might orbit the planet forever!

So how do astronauts get their tools, keep them from drifting away, and even make new ones when they’re millions of kilometers from home? Let’s open the cosmic toolbox and find out.

Pre-Packed Toolkits: Everything Planned Before Launch

Every space mission is planned down to the last screw. Engineers on Earth know exactly what repairs, experiments, and installations will happen — and they custom-design toolkits for those jobs.

Each astronaut’s tool pouch contains:

- Velcro straps and magnetic clips to keep tools from floating

- Color-coded handles to identify them easily

- Special shapes so they can be held while wearing thick space gloves

Some of these tools are one-of-a-kind — you won’t find a Pistol Grip Tool (NASA’s space drill) or a torque limiter at your local hardware store.

Delivered from Earth: Cargo Ships to the Rescue

When astronauts need new equipment or spare parts, cargo resupply ships bring them from Earth.

The International Space Station gets deliveries from:

- SpaceX Dragon (USA)

- Northrop Grumman Cygnus (USA)

- Progress (Russia)

- HTV Kounotori (Japan)

Each cargo ship docks automatically or via robotic arm. Once unloaded, astronauts store tools in labeled compartments for easy access.

Fun fact: even duct tape and zip ties are stored aboard — simple tools that often save the day!

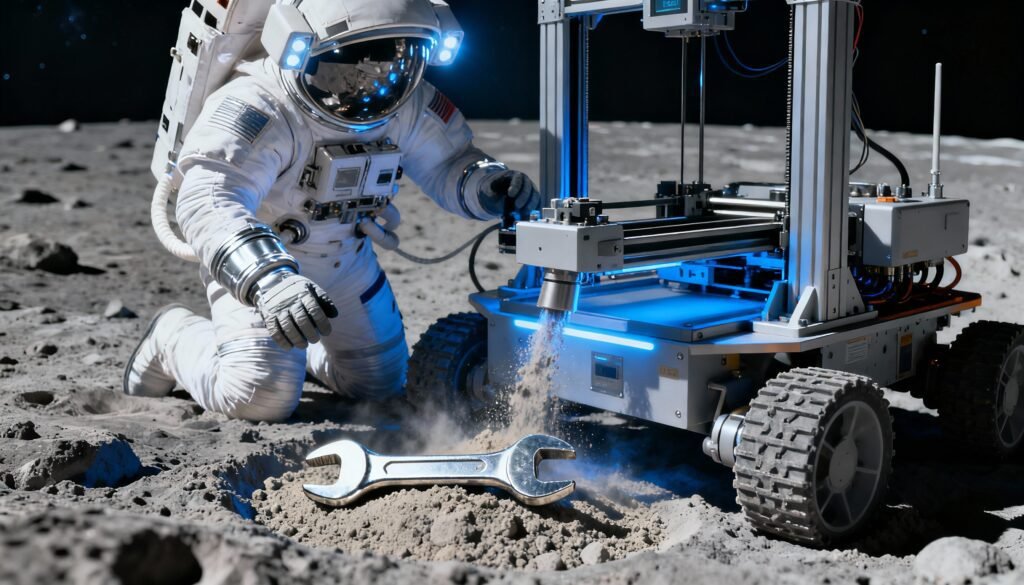

Printing Tools in Orbit: The 3D Revolution

What happens if something breaks and the spare doesn’t exist?

Astronauts can now 3D print tools in space.

NASA’s Made In Space project sent the first 3D printer to the ISS. In 2014, astronauts printed a ratchet wrench — based on a digital design sent from Earth.

This was revolutionary. For the first time, tools weren’t launched, they were created in orbit.

Benefits:

- No need to ship every possible spare

- Instant manufacturing in emergencies

- Digital designs can be updated remotely

Spacewalk Tools: Tethered, Locked, and Floated

When astronauts step outside for an EVA (extravehicular activity), every tool must be secured.

A single floating object could pierce solar panels or become dangerous debris. That’s why spacewalkers use:

- Tool belts with retractable cords

- Mechanical tethers that snap back if released

- Velcro pads inside their suits

Even the Pistol Grip Tool — NASA’s high-tech power drill — records torque, direction, and turns digitally to ensure every bolt is tightened perfectly.

Inventory in Orbit: The ISS Tool Database

Inside the space station, nothing can be misplaced. Every tool has a barcode and digital log in a system called Inventory Management System (IMS).

Astronauts scan tools when borrowing and returning them. This ensures that nothing floats behind a panel or drifts into a vent.

It’s like a cosmic library — but instead of books, it tracks screwdrivers and space drills!

Future Toolkits: Moon & Mars Missions

On future Moon or Mars bases, astronauts won’t rely solely on Earth shipments. They’ll:

- Bring modular toolkits that can adapt to different surfaces

- Use robots and drones to deliver tools during missions

- 3D print replacements using local materials (like lunar dust!)

Imagine crafting a wrench made from Moon soil — that’s the next level of off-world engineering.

Quick Recap

| Source | Description |

|---|---|

| Pre-Launch Kits | Tools packed before mission |

| Cargo Resupply | Delivered by Dragon, Cygnus, Progress |

| 3D Printing | Print custom tools in orbit |

| EVA Tethers | Prevent loss during spacewalks |

| Digital Inventory | Track every tool on the ISS |

| Future Missions | Robots + 3D printing on Moon/Mars |

A Symbol of Human Ingenuity

Every bolt tightened in orbit is proof of how far we’ve come.

Whether it’s a pre-planned wrench or a 3D-printed part, astronauts prove one thing again and again — human creativity travels well beyond Earth.

“In space, every tool tells a story — of planning, precision, and the power of problem-solving.”